In industries such as pharmaceuticals, cosmetics, and food and beverage, labeling accuracy and efficiency are critical to maintaining product integrity and brand reputation. Whether labeling square, flat, or round containers—including shampoo bottles, sauce packs, medicine bottles, or oil containers—improper labeling can lead to misplaced information, compliance issues, and an unprofessional appearance.

To tackle these challenges, SanTuo's Double Side Labeling Machine offers a reliable and high-speed solution for applying labels accurately to both sides of containers. Engineered for precision and durability, this system helps manufacturers minimize waste, reduce manual effort, and ensure consistent output in demanding production environments.

Common Labeling Challenges in Manufacturing

Labeling applications often face several persistent issues, especially when dealing with dual-side labeling on various container types:

-

Misalignment – Labels applied crookedly or inaccurately can lead to product rejection.

-

Speed Limitations – Many systems cannot maintain high accuracy at competitive production speeds.

-

Container Variability – Switching between square, flat, and round bottles often requires time-consuming adjustments.

-

Label Wrinkling or Bubbling – Poor adhesion or uneven application affects aesthetics and readability.

-

Downtime and Maintenance – Frequent breakdowns or parts wear can disrupt entire production lines.

SanTuo's double side labeling machine is designed to address each of these issues with advanced automation and robust engineering.

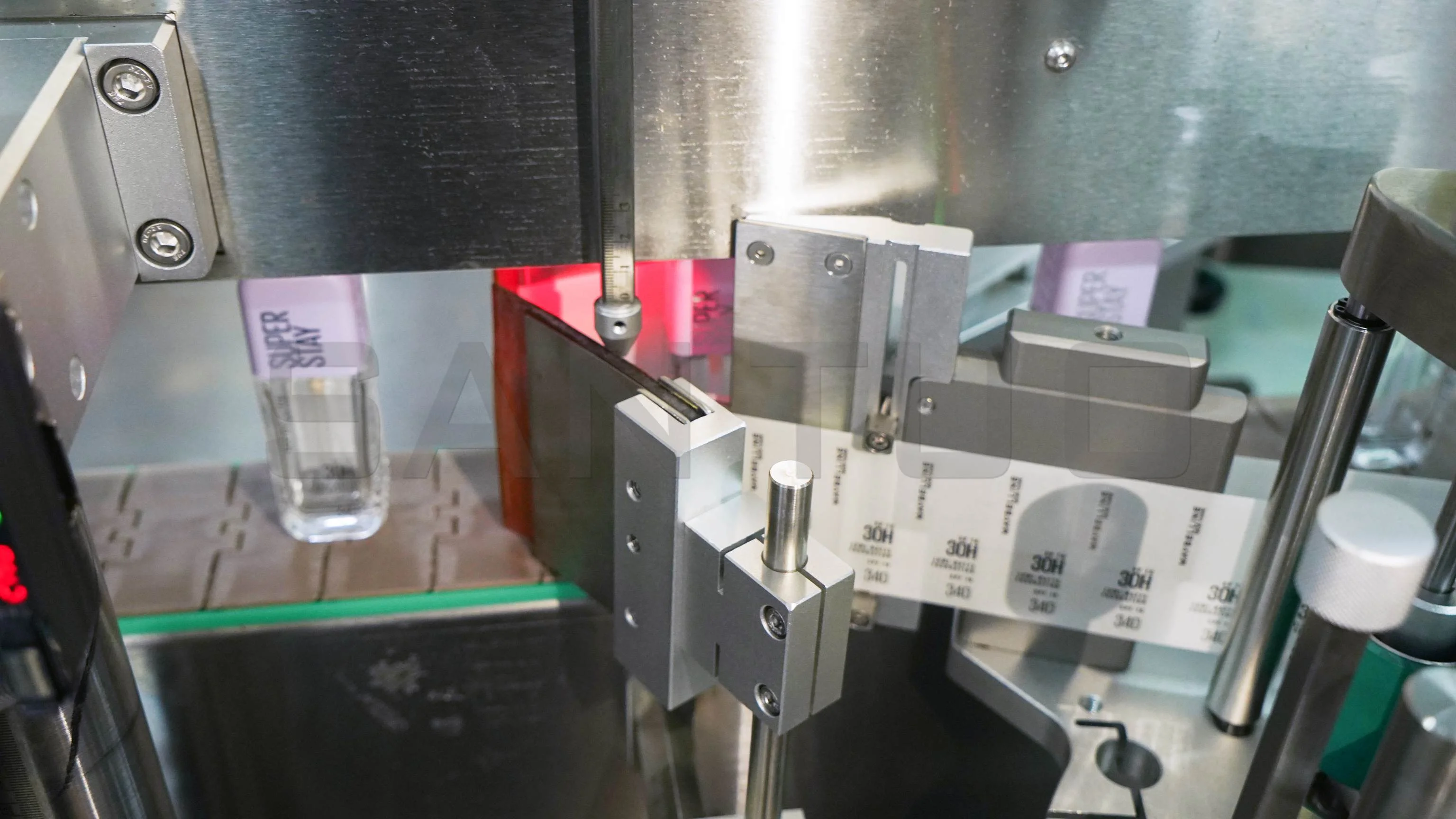

How the Double Side Labeling Machine Works

The labeling process is both efficient and precise:

-

Container Feeding – Products are transported via conveyor into the machine.

-

Separation and Alignment – A dividing wheel spaces containers evenly, while a dual correction belt ensures proper orientation.

-

Stabilization – An elastic top press holds each container securely in place without causing damage.

-

Label Application – Sensors trigger the labeling heads to apply labels simultaneously to both sides.

-

Smoothing and Inspection – Brushes ensure firm adhesion and smooth finish before containers move down the line.

This seamless process ensures high labeling accuracy and can be easily integrated into existing production setups.

Wide-Ranging Applications

SanTuo's machine is suitable for diverse industries and container types, including:

-

Pharmaceuticals – Medicine bottles, microcolumn gel cards

-

Cosmetics & Personal Care – Shampoo, conditioner, and lotion bottles

-

Food & Beverage – Sauce bottles, cooking oil containers, beverage bottles

-

Household Chemicals – Detergent and disinfectant bottles

Its flexible design allows quick adjustment between different container sizes and shapes, making it ideal for production lines with frequent changeovers.

Key Advantages of Choosing SanTuo's Double Side Labeling Machine

-

High Precision – Achieves labeling accuracy within ±1.5mm, ensuring consistently professional results.

-

High-Speed Operation – Capable of labeling 100 or more containers per minute, depending on container specifications.

-

Easy Adjustability – Equipped with rulers and intuitive controls to simplify size changeovers and reduce downtime.

-

Durable Construction – Made with stainless steel and aluminum alloy, meeting GMP standards for hygiene and corrosion resistance.

-

Versatile Labeling – Applicable for one-side or two-side labeling with reliable performance across materials.

Why Trust Santuo?

Santuo specializes in designing and manufacturing labeling solutions that help manufacturers improve efficiency and reduce operational costs. Our double side labeling machine reflects our commitment to quality, innovation, and customer satisfaction. With a focus on durability and ease of use, this machine is an ideal long-term investment for businesses looking to enhance their packaging quality and throughput.

Conclusion

Inaccurate labeling can cause costly reworks, compliance risks, and damage to brand image. Santuo’s Double Side Labeling Machine provides manufacturers across industries with a fast, precise, and adaptable solution for applying labels on both sides of containers. By integrating this system into your production line, you can achieve higher efficiency, reduce waste, and deliver a perfectly labeled product every time.